The Key Principles Of Lean Construction

-

Sapna

- March 21, 2024

Lean Construction Management (LCM) transforms the construction industry by prioritising efficiency and waste reduction. It emphasises maximising value and streamlining processes on job sites. This innovative approach differs significantly from traditional methods and focuses on a collaborative approach, data-driven decision-making, and enhancing project success.

In this blog, we will learn more about lean construction management, how it originated, and how it can be a perfect fit for your construction project management.

We will also explore and understand the basic practices and principles, eight types of waste, their benefits, and how Powerplay helps you implement lean construction in your project.

Table of Contents

ToggleWhat is Lean Construction?

Lean Construction is a method in the construction industry that focuses on reducing waste, improving efficiency, and optimising client value. It emphasises collaboration among all project stakeholders, including owners, architects, engineers, contractors, and workers. Lean Construction aims to streamline processes, reduce costs, and enhance quality.

Lean Construction aims to include the benefits of the Master Builder concept. It integrates project and production management principles to ensure that workflows are reliable and predictable on construction sites, maximising value and minimising waste.

The History of Lean Construction

Lean Construction is deeply rooted in the principles of Lean production, which were first applied in the manufacturing sector by companies like Toyota. The term “Lean Construction” itself was coined by the International Group for Lean Construction (IGLC) when it was founded in 1993. Glenn Ballard and Greg Howell, notable figures in the development of Lean Construction, started the Lean Construction Institute in 1997.

They introduced innovative tools and practices such as the Last Planner System, Target Value Design, and the Lean Project Delivery System, which have been instrumental in implementing Lean principles in construction projects.

Lean Construction is different from traditional construction management. It focuses on collaboration, continuous improvement, and optimising the entire project system rather than individual components. It aims to ensure that every phase of construction is aligned with the project’s goals, reducing waste and increasing efficiency.

Top Five Best Practices for Implementing Lean Construction

Implementing the best practices can lead to more efficient, cost-effective, and successful construction projects.

Here are five best practices for implementing Lean Construction:

Collaborative Planning and Scheduling: Engage all project stakeholders in the planning and scheduling process using techniques such as the Last Planner System. It ensures all the stakeholders are aligned with the project goals and contributes to identifying potential issues early on.

Waste Reduction: Focus on identifying and eliminating waste in the 3Ms of construction, i.e. material, men, and money. Regularly conduct audits to avoid material, manpower, and extra costs.

Continuous improvement: encourage continuous improvement by encouraging feedback and learning from both successes and failures. Use tools like Plan-Do-Check-Act (PDCA) cycles to test changes and implement best practices.

Integrated Project Delivery (IPD): Use IPD contracts to align the interests of all project participants, including the owner, designer, and builder. This collaborative approach promotes shared risk and reward, driving innovation and efficiency.

Data-Driven Decision Making: LCM relies on data and metrics to inform decision-making processes, allowing project teams to identify trends, predict outcomes, and make informed choices. By leveraging technology such as Building Information Modeling (BIM) and project management software, LCM enables more accurate planning and resource allocation.

Key Principles

Toyota developed the principles of Lean Manufacturing, and various researchers, such as Lauri Koskela, Greg Howell, and Glenn Ballard, have collaborated to adapt these principles to the construction industry.

These principles help reduce costs, improve quality, enhance safety, and ensure timely project completion, ultimately leading to higher client satisfaction and better project outcomes.

The key principles are as follows:

Define Value: Conduct interviews or directly engage with owners to understand their needs and requirements, such as focusing on energy efficiency or sustainable materials, and ensure the final construction meets their exact expectations.

Map the Value Stream: Map out all steps from initial design to final execution, identifying and eliminating unnecessary steps like redundant approval processes or excessive material handling.

Create Flow: Schedule work sequences efficiently so that as soon as one task is completed (like foundation setting), the next task (like framing) begins immediately, avoiding downtime.

Establish Pull: Establishing pull is very important. For example, if there is any housing development project, start construction of new units based on actual sales or interest from buyers rather than building all units in advance.

Pursue Perfection: After completing a project, conduct a thorough review to identify any inefficiencies or waste encountered during construction. Use these insights to improve processes in future projects.

Benefits of lean construction

Implementing lean techniques in your construction business can offer various benefits, such as:

- Reduced Waste: Implementing this methodology at your job site will help you use materials and resources more effectively.

- Improved Productivity: Streamlined processes lead to faster project completion.

- Higher Quality: Focus on value, which leads to better-quality outcomes.

- Enhanced Safety: Cleaner and more organised job sites reduce accidents.

- Cost Savings: Efficiency leads to lower operational costs.

Transitioning to lean construction means growth and transformation.

Transitioning to Lean Construction is a transformative process that leads to growth and improved efficiency in construction projects. However, merely adopting these principles and best practices will not effectively achieve LCM. It also needs an effective shift in mindset and behaviour, as it contradicts long-standing practices.

Maintaining the importance of urgency, leadership, focus, structure, discipline, and trajectory during projects is crucial for transforming construction processes and effectively adopting Lean principles.

Reduce Waste in Construction

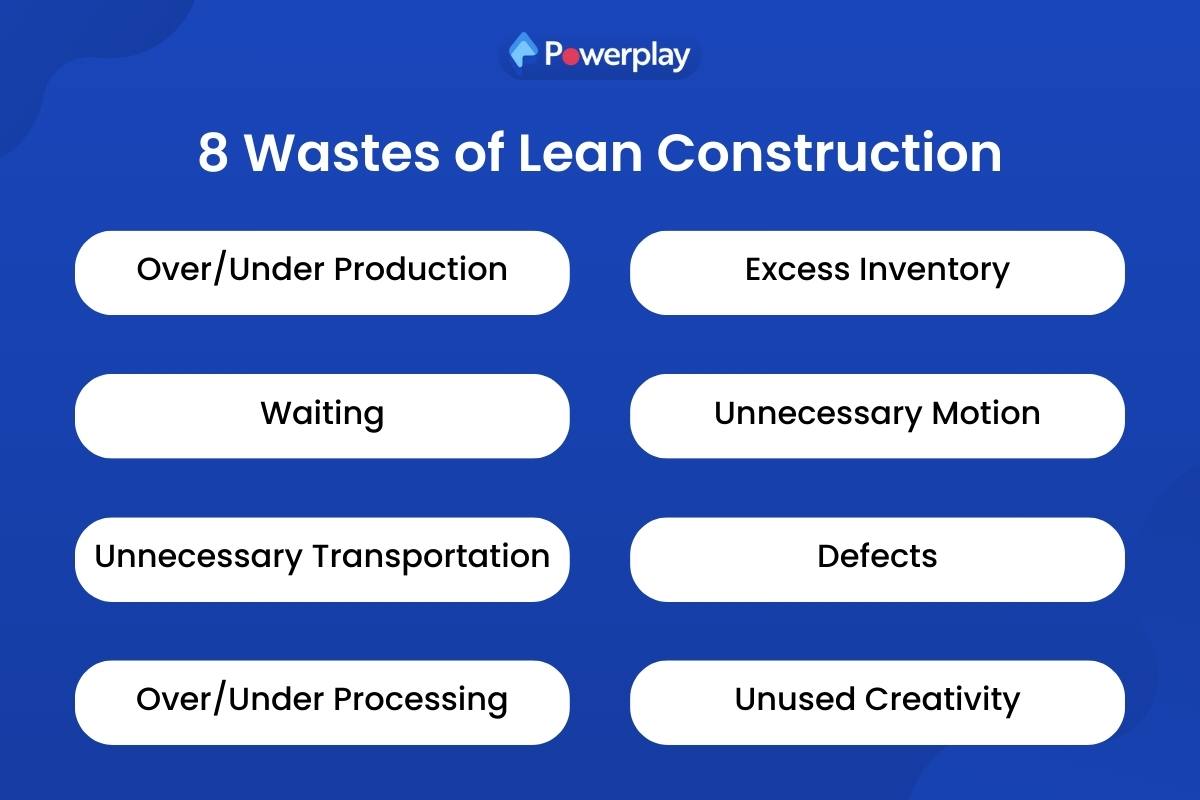

Reducing waste in construction is a critical aspect of Construction. It aims to enhance efficiency and minimise unnecessary expenses. It identifies eight types of waste, and addressing each of these can lead to significant waste reduction.

The eight wastes of LCM are:

- Over/Under Production: Producing more than needed will result in excess inventory, and producing less will cause delays. These scenarios will disturb the project flow.

- Waiting: Delays occur when workers, materials, or information are not ready when needed, causing wastage of time.

- Unnecessary Transportation: Excessive movement of materials, equipment, or information leads to wasted time, potential damage, and increased costs.

- Over/Under Processing: Doing more work than necessary or not doing enough will lead to inefficiencies, either through wasted effort or the need for rework.

- Excess Inventory: Holding more materials or information than required consumes valuable resources and space, leading to potential waste.

- Unnecessary Motion: The movement of workers that doesn’t add value to the project leads to wasted time and can increase the risk of safety issues.

- Defects: Errors or the need for rework due to mistakes or poor quality control result in wasted materials, time, and effort.

- Unused Creativity of Team Members: Failing to leverage the skills, ideas, and knowledge of workers leads to missed opportunities for improvement and innovation

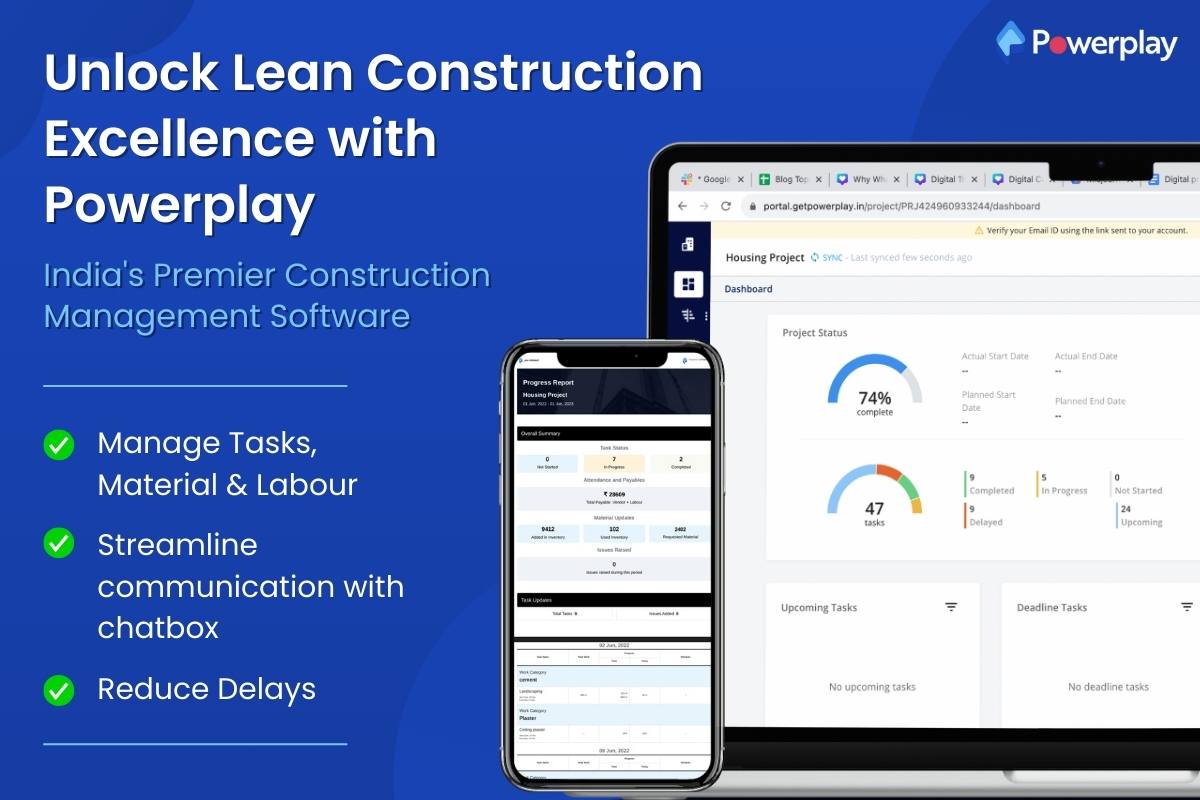

Lean Construction Management With Powerplay

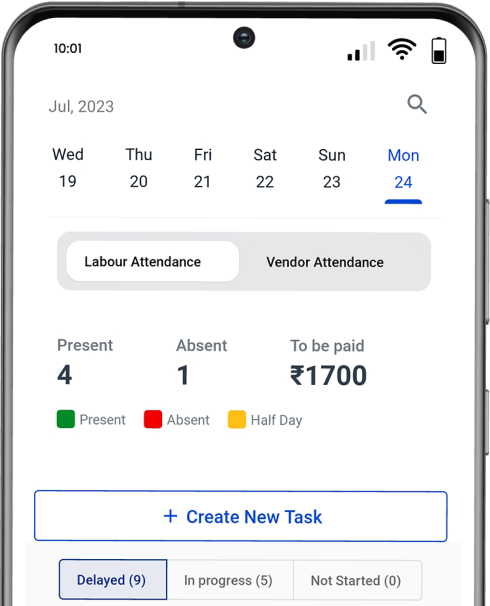

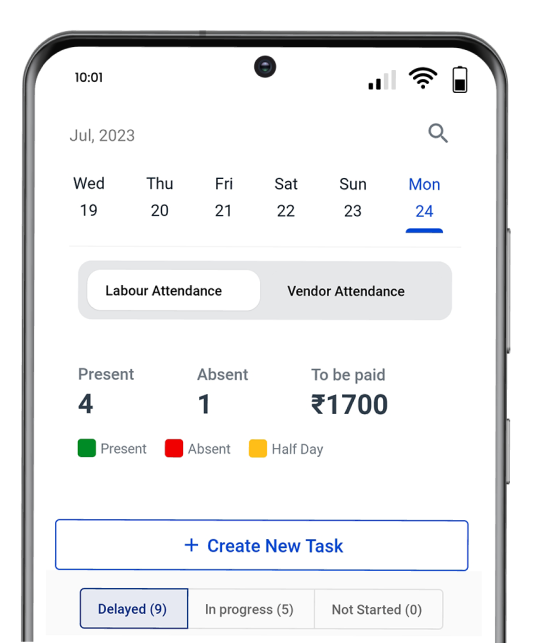

Powerplay, India’s most trusted construction management software, is the best tool for implementing all the best practices in lean construction. Powerplay offers features such as material management, labour management, chatbox, snag finder and task management.

Material Management: This feature, users can ensure the right materials are available at the right time and in the right quantities. They can also track material usage, predict future needs, and automate reordering processes. This will help prevent delays caused by shortages or excess inventory and facilitate better inventory management and cost control.

Labour Management: This feature will help allocate labour resources, which is essential for optimising productivity and minimising project costs. It enables project managers to assign tasks, monitor workforce utilisation, and streamline labour workflows. It reduces unnecessary worker movements and ensures that each worker is deployed effectively, helps maximise efficiency on the job site.

Chatbox: This feature enhances collaboration among all the stakeholders. By providing a centralized platform for instant messaging and real-time updates, it enables swift decision-making and reduces the need for time-consuming meetings or email exchanges.

Project Management: This feature facilitates project planning, execution, and monitoring. It includes task tracking, scheduling, budgeting, resource allocation, and progress reporting. Users can mitigate risks by providing project managers with comprehensive visibility into project status and performance, leading to smoother project delivery and improved outcomes.

Snag Finder: Powerplay also offers a feature where users can identify, document, and track defects or “snags” that must be addressed. They can click pictures and share them by adding the necessary details. It will help recognize the default materials and improve accountability.

Powerplay also provides many user-friendly features that help manage projects more efficiently and effectively. So embrace Powerplay in your projects to implement LCM, download the easy-to-use mobile application Powerplay, and start building your dream project.

Conclusion

LCM is an effective process in construction project management. According to reports, embracing Lean principles in construction projects has brought significant improvements. Reports also indicate that projects that adopt Lean management have a potential 10-30% reduction in project costs and a 20% decrease in completion time. Moreover, efficiency in resource utilisation has been increased by up to 20%.

These statistics underscore the role of Lean Management in enhancing profitability. By minimising waste, optimising resources, and improving timelines, construction companies not only save costs but also boost their overall competitiveness. As the construction industry evolves, Lean Management will play an important role in shaping its future.