Different Types of Steel Used in Construction by Top Contractors

-

Sapna

- March 15, 2024

Steel plays a crucial role in construction. Its high tensile strength makes it ideal for constructing buildings, bridges, and other structures that require durability and resistance to heavy loads.

It is primarily composed of iron and carbon. Additionally, the carbon content typically ranges from about 0.05% to 2%, influencing the steel’s strength, ductility, and weldability.

Steel is renowned for its high strength-to-weight ratio, making it capable of withstanding heavy loads and adverse weather conditions. It doesn’t warp, buckle, twist, or bend easily, providing long-term structural integrity. Due to its impeccable abilities, its production is exceeding to 1.3 billion tonnes annually.

Moreover, each type of steel offers unique properties that cater to specific construction needs, whether strength and stability provided by structural steel, reinforcement capabilities provided by rebar, or corrosion resistance and aesthetics delivered by stainless steel. By selecting the appropriate type of steel for the intended application, builders and engineers can ensure the structural integrity, longevity, and performance of construction projects.

Table of Contents

ToggleImportance of Steel

Steel plays a pivotal role in construction endeavours, serving as a fundamental material for building projects worldwide. Renowned for its robustness, longevity, Fire resistance, and adaptability, steel reinforces structures ranging from buildings and bridges to towering skyscrapers. This resilience enables these constructions to endure substantial loads and adverse environmental conditions with steadfast reliability.

Steel’s recycling ability makes it an eco-friendly option. Additionally, its resistance to fire, earthquakes, and corrosion makes it important in constructing safe and long-lasting structures. Overall, steel’s unique properties make it an essential material in the construction industry.

Best Types of Steel Used in Construction

There are different types of steel used in the construction. Structural steel, carbon steel, rebar steel, alloy, and mild steel (MS) are some of the most commonly used types of steel by top contractors. In the following sections, let’s explore each of them in detail.

Structural Steel

Structural steel is known for its high strength, elasticity, and durability, making it ideal for constructing buildings and bridges. These types of steel can be moulded into various shapes, such as I-beams, L-beams, Z-beams, allowing design flexibility. It is used in construction of skyscrapers, bridges, industrial buildings, high-rise offices, residential buildings, stadiums, etc. The structural steel price in India varies, generally ranging from ₹60 to ₹75 per kg.

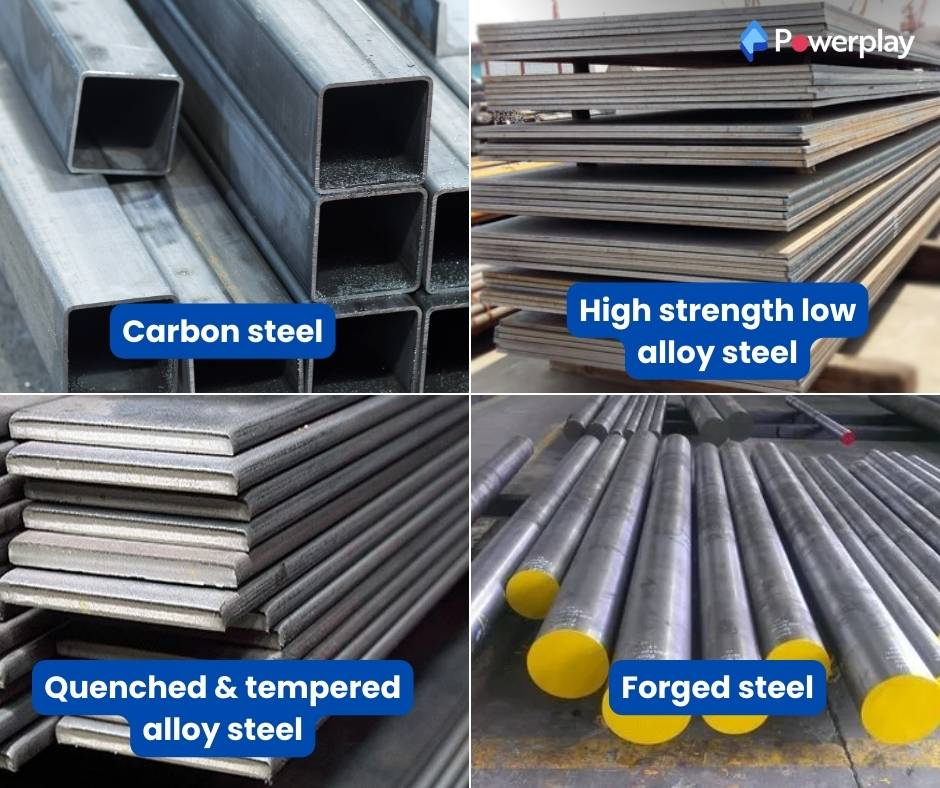

Types of Structural steel

- Carbon Steels: Carbon steels are characterised by a high carbon content, providing strength and rigidity, making them suitable for structural applications. They are various types of carbon steel such as low carbon, high carbon, medium carbon, etc.

- High-Strength Low-Alloy Steels: These are alloyed with various elements to improve their mechanical properties and corrosion resistance, offering a higher strength-to-weight ratio.

- Quenched and Tempered Alloy Steels: They undergo heat treatment to enhance their strength, toughness, and wear resistance, making them ideal for heavy-duty construction.

- Forged Steel: Forged Steel involves shaping the metal while solid, resulting in a uniform grain structure.

Rebar Steel

Rebar or reinforcing steel provides tensile strength to concrete structures, enhancing their stability and durability. It is commonly used in the construction of earthquake-resistant buildings and to withstand natural calamities. The market price in India varies based on type and quality, typically ranging from ₹40 to ₹60 per kg.

Types of Rebar Steel

- Plain steel wire

- Epoxy-coated bars

- TMT bars

- Galvanised Rebar

- Welded Wire Fabric

Alloy Steel

Alloy steel is one of the most used steel. It adds chromium, nickel, and molybdenum to carbon steel, enhancing its strength, hardness, corrosion resistance etc. Due to its unique characters Alloy steel is used in various sector such as automotive parts, pipelines, and tools. The price of alloy steel can vary widely depending on alloying elements used, generally ranging from ₹70 to ₹200 per kg.

Types of Alloy steel

- High Alloy Steel

- Low Alloy Steel

Stainless Steel

It is known for its corrosion resistance, making it ideal for use in environments prone to corrosion, such as kitchen appliances, medical equipment, construction, etc. It contains chromium, which forms a protective layer on the surface. The price in India ranges from ₹180 to ₹250 per kg, depending on the grade.

Types of stainless steel

- Austenitic stainless steel

- Ferritic stainless steel

- Martensitic steel

Mild Steel (MS)

Mild steel, or low-carbon steel, is known for its malleability and weldability, making it suitable for construction, automotive parts, and machinery. Its lower carbon content makes it less brittle. The market price in India for mild steel is relatively low, typically ranging from ₹45 to ₹60 per kg.

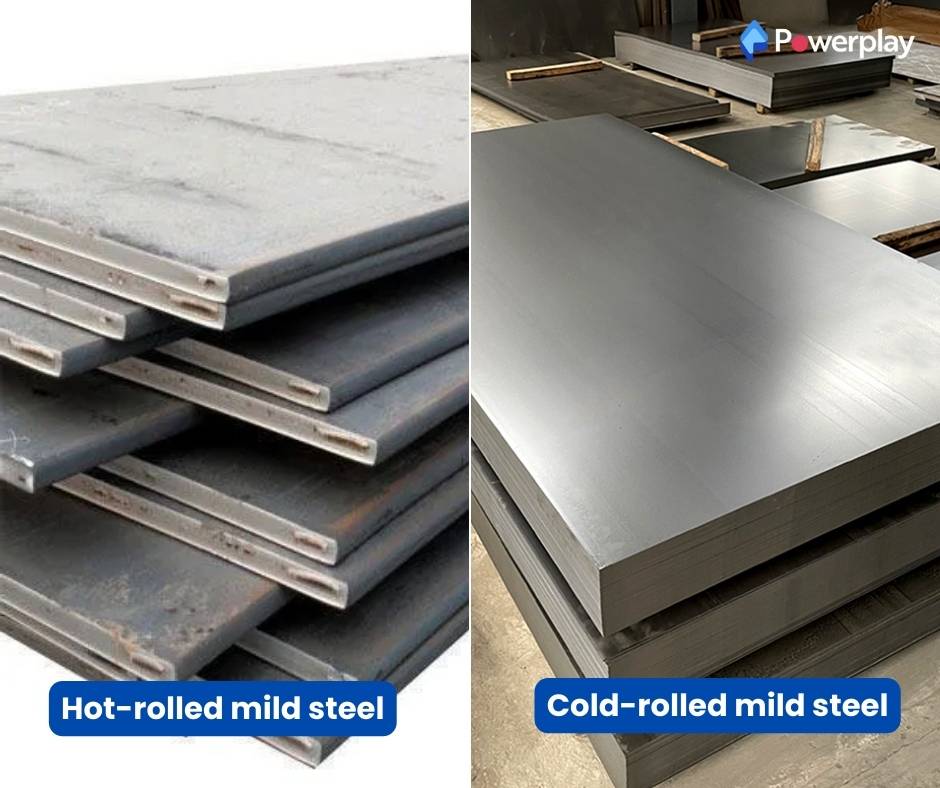

Types of Mild steel

- Hot-rolled mild steel

- Cold-rolled mild steel

Tool Steel

The tool steel is known for its hardness, abrasion resistance, and ability to retain shape at high temperatures. It manufactures tools, moulds, dies, and cutting equipment. The price of tool steel can vary significantly depending on the specific grade and composition, but it generally ranges from ₹200 to ₹500 per kg in India.

Types of Tool steel

- Water-hardening (W-grades)

- Air-hardening (A-grades)

- D-type (high carbon-chromium steels)

- Shock-resisting (S-grades)

- Hot-working (H-grades)

Light Gauge Steel

Light Gauge Steel is in the from of thin sheets of steel that stick to strict specifications. these types of steel used in residential and commercial construction for framing due to its lightweight and high strength-to-weight ratio. LGS offers design flexibility, faster construction times, and resistance to pests and fire. The price of Light Gauge Steel in India typically ranges from ₹50 to ₹70 per kg.

Links to Buy Some of the Best Steels

Here are some of the top brands in India to buy different types of steel:

- Tata Steel offers a wide range of steel products, including TMT bars, structural steel, and flat products like hot-rolled, cold-rolled coils and sheets.

- JSW Steel provides high-strength and advanced high-end steel products for automotive segments, as well as carbon steel, hot-rolled, cold-rolled, and galvanized sheets.

- ArcelorMittal Nippon Steel India offers over 300 steel grades, including hot-rolled, cold-rolled, galvanized, pre-painted sheets and plates.

- Steel Authority of India Limited (SAIL) produces a wide range of steel products, including TMT bars, structural steel, and flat products.

How Powerplay Can Help You

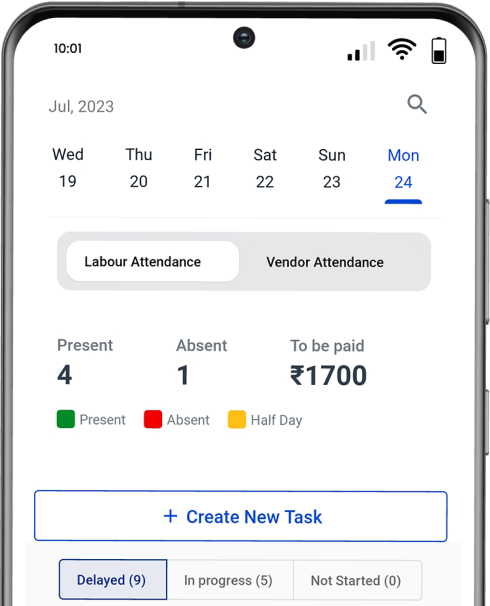

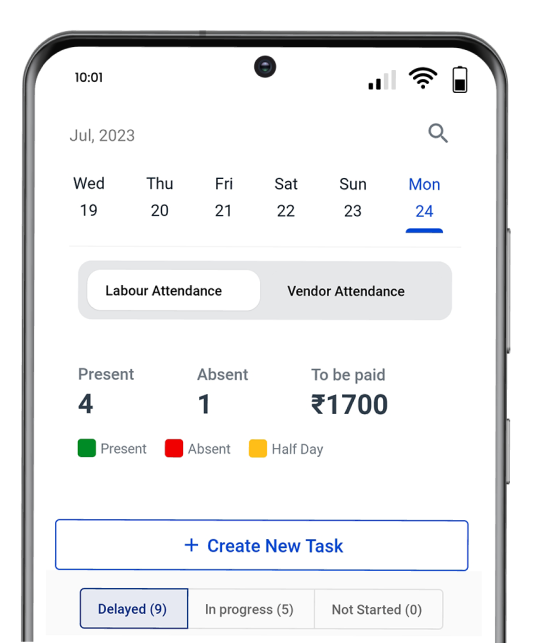

Once you’ve selected the ideal steels for your project, consider integrating the Powerplay app into your projects. This app helps you manage and monitor the quantity of steel purchased, tracks deliveries in real-time, and ensures accurate tracking of the steel required for the project. With Powerplay, you can effortlessly keep tabs on when and how much steel is required on-site, minimising waste and optimising resource allocation.

Moreover, It also offers easy-to-adopt features to handle various aspects of your project, including vendor coordination, task scheduling, and labour management. So download Powerplay and with the help of Powerplay you can ensure the smooth operation of your construction project.

Conclusion

Steel has long been indispensable to the construction industry, offering unparalleled strength, durability, sustainability, and enhancing structural integrity. The World Steel Association forecasts a promising future for steel, with global demand anticipated to increase by roughly 1.9%, reaching approximately 1,849 million tonnes. As the industry progresses, advancements in steel production have the potential to bolster sustainability and efficiency, reaffirming steel’s pivotal role in shaping the future of construction worldwide.

A contractor should thoroughly understand the different types of steel and their specific properties, as this will help them make an informed decision about choosing suitable steels for their projects.