Construction Inventory Management: A Simple Guide

-

Kumar Abhishek Anand

- March 20, 2024

Inventory management in the Construction industry is a critical facet of the construction industry, one that directly impacts project timelines, budget adherence, and overall success. The advent of construction inventory management software has significantly refined the way construction firms handle inventory, ensuring a seamless, accurate, and efficient process. This article delves into the intricacies of inventory management within the construction realm, spotlighting the revolutionary role of software solutions.

Before we jump into the construction inventory management software, let us learn about the types of inventory in the construction industry and the Challenges related to Construction Inventory Management.

Table of Contents

ToggleTypes of inventory in Construction:

- Building Materials: In a construction project or construction site, building materials are the backbone. It includes all the raw materials required to build or construct any project, like – bricks, cement, steel, lumber, electrical wiring, and other elements specific to the construction phase.

- Tools and Equipment: Having a good range of this construction inventory ensures smooth operation and timely completion. From welding equipment to heavy machinery like cranes, everything is included under this category.

- Consumables: Often overlooked, consumables like fasteners, welding rods, safety gear, and cleaning supplies are crucial for day-to-day operations.

The Challenges of Construction Inventory Management:

- Accurate Tracking: Many construction businesses use manual tools to keep the records of their construction inventory and hence there are always errors. Real-time data on material usage, equipment deployment, and stock levels is very essential for informed and faster decision-making.

- Theft: Not all construction sites have a robust security system, therefore construction sites become vulnerable to material and equipment theft very easily.

- Uncertain timeline: Supply chain fluctuations in raw material prices can significantly impact project timelines and budgets.

- Project Delays: Using manual methods can cause unexpected delays in construction projects and this can lead to higher construction costs.

3 ways for better construction inventory management

Every construction project site has a surplus construction inventory for everyday construction needs. A large amount of construction inventory even gets wasted because of no proper management which results in higher construction costs. Therefore, to minimise this loss and boost the optimum utilisation of inventory, every construction owner, project manager, and site engineer must adapt the below five ways for good construction inventory management:

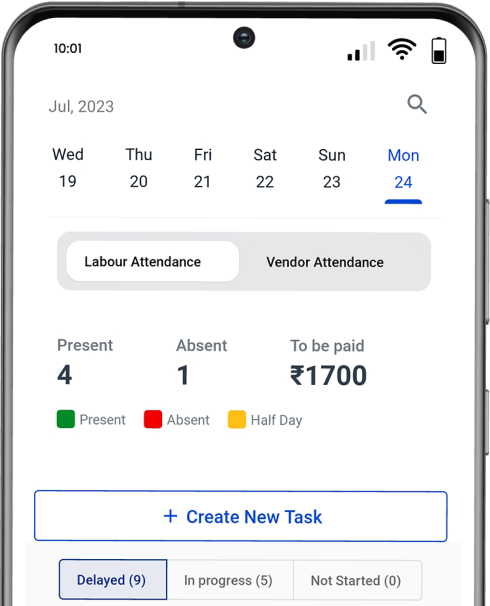

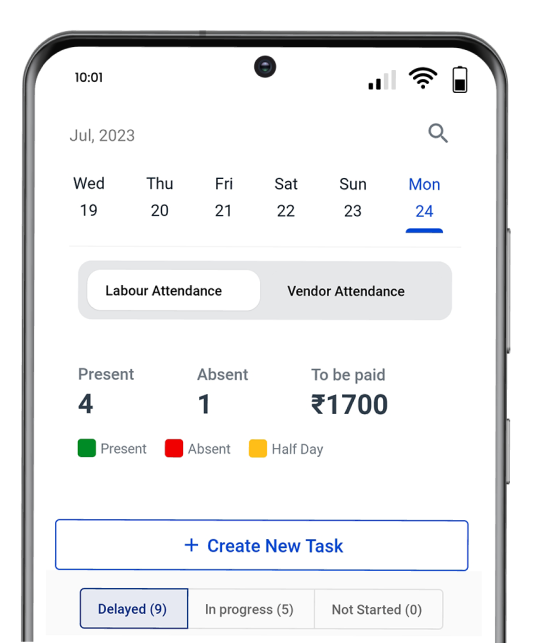

- Adopt Technology:

Using an inventory management system can sort a lot of pain points and blockers involved in managing the construction inventory. It can make the entire process of tracking stock, raising material requests, generating POs, and keeping an eye on delivery easy with a click. Most inventory management systems are available on iOS, Android, and the Web, hence everyone can use them. As all the inventory-related data is available on the app or system, a site engineer or project manager doesn’t have to repeatedly coordinate with procurement managers from the office team. - Planning and anticipation:

Like every other work in construction, inventory management also has to be a planned task without which everything else can stand still. With no inventory at the site, labourers may not be able to work. Therefore, there shouldn’t be a single day when there is no inventory at the construction site. To make this happen, the project managers need to plan their daily inventory better and using a digital solution can help them plan and anticipate their requirements better so that the site is functional at all times. - Always keep track of delays:

First, inventory delays should never happen. They can negatively impact your construction timelines. Setting automated alerts or notifications when the inventory stock is low can help project managers order inventory in time and avoid delays.

Software solution for Construction Inventory Management

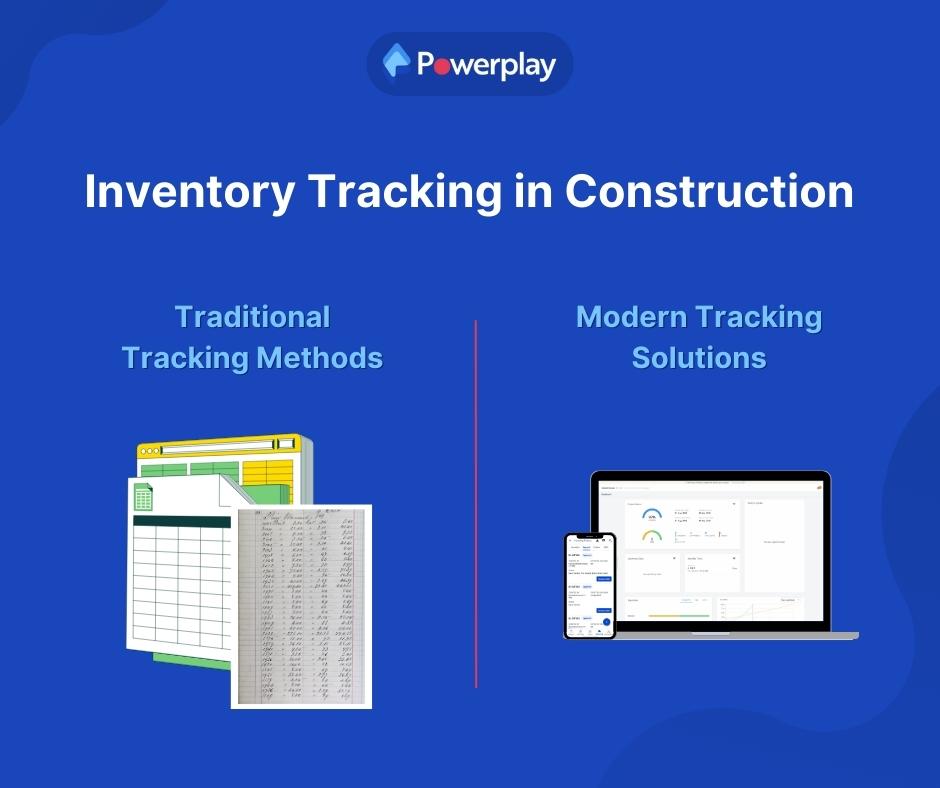

1. Inventory Tracking in Construction

-

Traditional Tracking Methods:

– Historically, construction companies relied on manual methods like spreadsheets or paper-based systems to keep track of inventory. These methods, while straightforward, are prone to errors and inefficiencies.

-

Modern Tracking Solutions:

– The digital age ushered in construction inventory software, a tailored solution enabling real-time tracking, accuracy, and data-driven decision-making.

– Your brand, with its robust web and mobile-based software, exemplifies a holistic approach to construction project management, encompassing not only material inventory but a wide spectrum of project-related tasks.

-

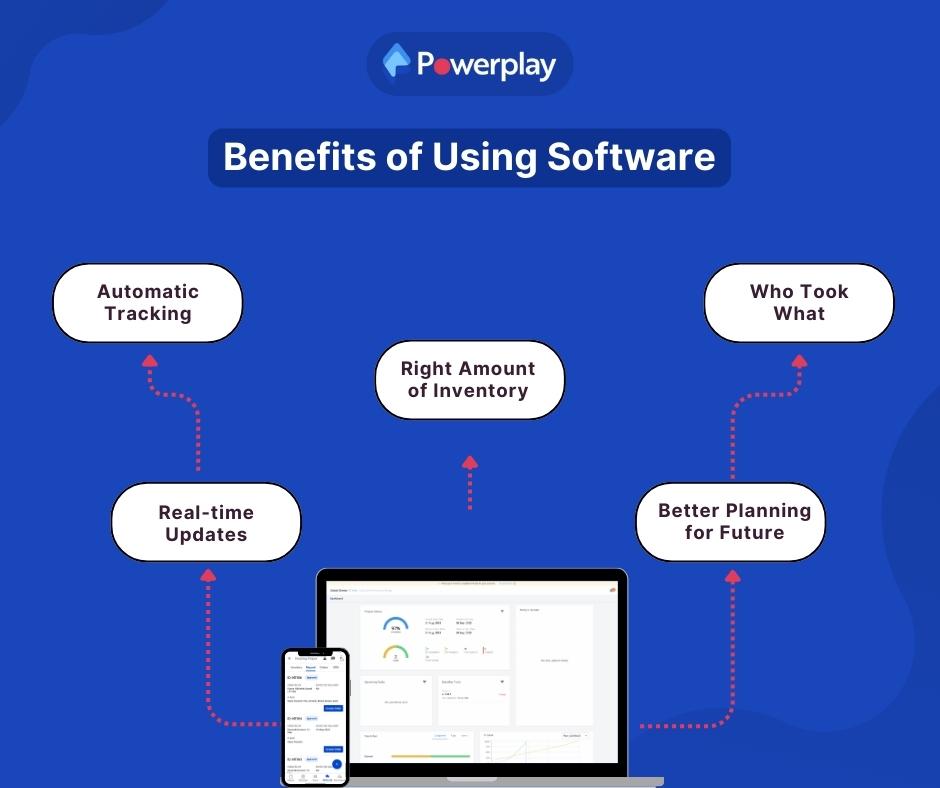

Benefits of Using Software:

– Automatic Tracking: The software keeps track of materials and tools automatically, saving a lot of time.

– Real-time Updates: Get immediate updates on what is available, which helps in planning the work better.

– Right Amount of Inventory: The software helps in keeping the right amount of materials, so there is no waste of money.

– Who Took What: Know who took which material or tool, which helps in managing the team better.

– Better Planning for Future: The software helps in understanding the usage of materials better, which helps in planning future projects.

2. Unpacking Inventory Management in Construction

-

Defining Inventory Management:

– Inventory management entails the systematic control of materials, equipment, and other resources throughout the project lifecycle.

– The types of inventory in a construction company range from raw materials, work-in-progress, to finished goods, each requiring meticulous management.

-

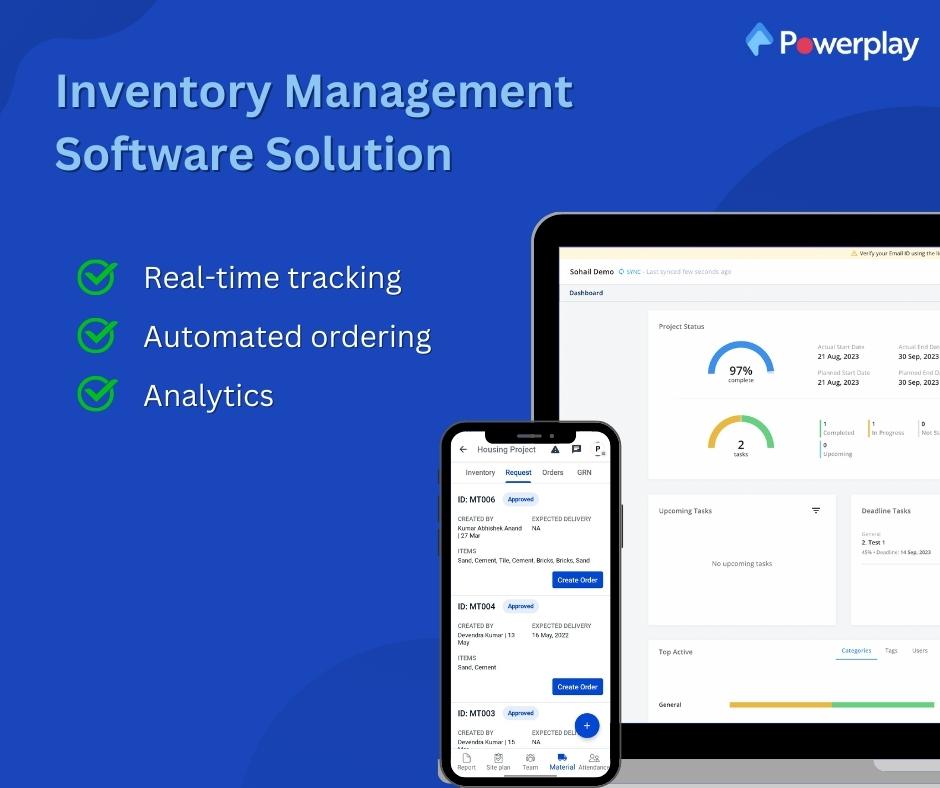

Software Solutions:

– Various software solutions cater to inventory management, with features like real-time tracking, automated ordering, and analytics.

– The inventory management software, like the one offered by your brand, encapsulates a range of functionalities ensuring effective inventory control, vendor management, and financial oversight.

3. Construction Inventory Management Software Solutions

-

Inventory Management Software Landscape:

– The market is replete with software solutions designed to tackle the unique challenges of inventory management. They range from standalone inventory software to comprehensive construction project management platforms encompassing inventory management as a core functionality.

-

Your Brand’s Offering:

– Your brand stands out with its web and mobile-based software, offering a holistic solution for managing every facet of construction projects. The inventory management system for company operations within your software facilitates:

– Real-time tracking of material inventory.

– Managing daily tasks, labor attendance, wages, bills, and vendor relations seamlessly.

– Employing inventory management software to ensure accuracy, timeliness, and efficiency in inventory operations.

-

Comparison with Other Inventory Management Software:

– When compared to other software, your brand’s inventory software for construction company management provides an intuitive interface, robust features, and the flexibility to cater to diverse construction project needs. It’s not merely about managing inventory; it’s about empowering construction firms to have a granular control over every aspect of their projects, driving better outcomes.

4. Elevating Inventory Management Practices

-

Improvement Strategies:

– Implementing a centralized inventory management system for company operations to ensure real-time tracking and accurate data capture.

– Regular training for staff on the latest inventory management software to optimize utilization and efficiency.

-

Software Solutions:

– Leveraging inventory management system features like automation, analytics, and real-time monitoring to significantly improve inventory practices.

Dive into Inventory Tracking Methods

-

Tracking Techniques:

– The three methods of tracking inventory include perpetual, periodic, and just-in-time inventory management.

– The most common method, perpetual inventory management, is facilitated effortlessly by modern construction inventory tracking software.

Best Practices for Managing Inventory

-

Effective Management:

– Adopting a robust construction inventory software ensures accurate order placements, timely deliveries, and minimizes holding costs.

– Prioritizing accuracy and real-time data access as the most important thing in inventory management.

How construction inventory management systems differ from other inventory management systems

A generic inventory management system does not have the specifications required for the construction business and will do more harm than good. An inventory management system designed specifically for the construction industry will have specifications which support different types of construction assets. Building materials, tools, equipment, and consumables are a few key construction assets which are required during the construction of any project, and they all are measured differently.

A generic inventory management system doesn’t provide you the freedom to manage your inventory in different tracking requirements. For instance, items like cement are generally tracked in bulks and a crane is tracked individually. Some items even get entirely consumed on the site while some need to be transferred back to the office or warehouse. It is only the construction inventory management solution which can provide such flexibility and not a generic inventory management system.

What else to look for when selecting a construction inventory management system?

Product interaction with your existing system, adaptability, reporting, and analytics are a few essentials you must consider while selecting a construction inventory management system. Managing construction inventory is a critical process of your business operations, there it is a must that it should be a user-friendly system which can be easily used by project managers and site engineers. Getting quick, instant, and real-time reports and analysis is extremely important for you to make informed business decisions faster. It is these features which will generate positive ROI for your business at large.

The Significance of Inventory in Construction

-

Why Inventory Matters:

– Inventory is the lifeblood of construction projects, directly influencing project timelines, costs, and profitability.

– Inventory management software serves as a catalyst for maintaining a well-organized, cost-effective inventory system.

Conclusion

Inventory Management System in the construction industry is an indispensable aspect of construction project success. The emergence of sophisticated inventory software for construction has significantly alleviated traditional challenges, paving the way for enhanced efficiency, cost savings, and project excellence. By adopting modern inventory management solutions like the one offered by your brand, construction firms are well-poised to streamline operations, ensure project success, and achieve a competitive edge in the bustling construction industry landscape.

Share

Kumar is a digital content professional with more than 2 years of experience in Blog writing, copywriting and scripting. His passion lies in the art of creating convincing content that plays a major role in converting leads for SAAS businesses.