Material Management In Construction – A Simple Guide

-

Kumar Abhishek Anand

- April 3, 2024

Ever wondered why your construction project, which was all set to be completed within budget, ended up emptying your pockets? The answer might lie within the dusty old ledgers and disorganised stacks of receipts, proof of the traditional practices of recording and maintaining material usage. You guessed it right! Poor material management in construction projects has been a consistent reason in the history of cost overruns.

Table of Contents

ToggleWhat is Construction Materials management?

Material management in construction is the process of procuring, allocating, and disposing of construction materials. It’s more than just purchasing and delivering materials. It involves a wide array of activities aimed at sourcing materials on time and at a reasonable cost for every construction project. It’s safe to say that this process is vital as it ensures meeting project goals.

Objectives Of Material Management In Construction

Material management in construction is not just about the construction of raw materials on the project site. It has to be a strategic approach with clear objectives and goals:

Resource Optimisation

Optimising the usage of construction resources and ensuring that every raw material is efficiently utilised throughout the project lifestyle is the top priority of every construction business. This optimisation minimises waste and maximises the value derived from available resources and raw materials.

Timely Availability

The primary objective of any construction project manager is to make sure that the construction raw materials are in adequate quantity at all times. Timely availability of construction materials prevents project delays, streamlines project schedules, and enhances the overall project efficiency.

Cost Control

Every construction owner and project manager is looking to optimise the construction cost without compromising on the quality. Therefore, controlling costs via efficient material management is fundamental for every construction business. By effectively managing materials, construction companies can prevent budget overruns, enhance profitability, and maintain competitiveness in the market.

Quality Assurance

Material management encompasses maintaining strict quality standards for all materials utilised in construction projects. Ensuring quality assurance guarantees the longevity, safety, and reliability of the constructed infrastructure.

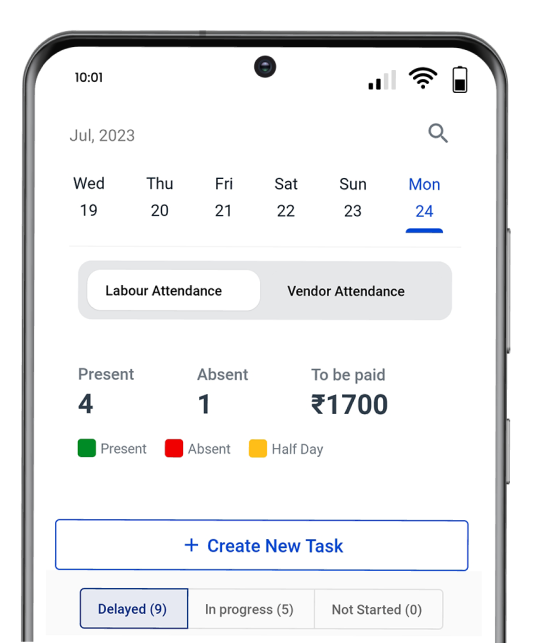

Key Aspects of Planning Construction Materials Management

Inventory Management

Accurate and efficient inventory management is paramount. It involves tracking material quantities, locations, and usage patterns to facilitate informed decision-making regarding procurement, storage, and distribution.

Supplier Relationships

Cultivating robust relationships with suppliers is crucial for reliable and timely access to materials. Strong supplier relationships can lead to preferential pricing, priority deliveries, and access to high-quality materials.

Storage and Handling

Proper storage and handling procedures are essential to preserve the quality and integrity of materials. Adequate storage facilities, climate control measures, and appropriate handling techniques mitigate the risk of damage, spoilage, or deterioration.

Transportation Logistics

Planning transportation logistics optimises the movement of materials from suppliers to construction sites. Efficient transportation routes, modes of transport selection, and scheduling minimise transit times, reduce costs, and mitigate logistical challenges.

Challenges In Implementing Material Management

While the traditional methods of manual or pen-and-paper material management in construction have served the industry for a long time, these practices are increasingly being recognised as inefficient and error-prone, leading to several pain points for different stakeholders.

For the construction owner, manual material management can lead to budget overruns and missed deadlines due to the lack of real-time visibility into the inventory levels and the status of material procurement and usage. Moreover, this lack of transparency can lead to strained relationships with clients who demand accountability and progress updates.

Clients, on the other hand, are affected by the inability to accurately forecast project completion times and costs due to inefficient material management. This uncertainty can negatively impact their own planning and budgeting processes.

For site engineers/supervisors, manual material management often means additional workload, as they have to constantly update inventory records, track material usage, and coordinate with suppliers. Furthermore, the lack of a centralised system can lead to miscommunication and errors, ultimately affecting the overall project execution.

The issues faced in traditional material management are:

Lack of Real-Time Visibility

Traditional methods do not provide real-time updates on inventory levels and material usage, leading to inefficiencies and potential delays.

Budget Overruns

Manual tracking can lead to errors in procurement and usage, leading to budget overruns.

Inaccurate Forecasting

The inability to accurately forecast material needs can lead to project delays and increased costs.

Increased Workload for Site Managers

Without a centralised system, site managers are left to manually update inventory records and coordinate with suppliers.

Lack of Accountability

Without a clear and transparent tracking system, it’s hard to establish accountability for material usage and procurement.

Strained Client Relationships

The lack of transparency and the potential for delays and cost overruns can strain relationships with clients.

Best Practices For Construction Materials Management

Centralised Procurement

Centralising procurement processes streamlines purchasing activities, standardises pricing, and ensures consistency in material quality across projects. Centralised procurement facilitates bulk purchasing, volume discounts, and improved supplier negotiations.

Technology Integration

Leveraging advanced technologies such as construction management software or inventory management systems automates material tracking, enhances accuracy, and improves overall operational efficiency.

Regular Auditing

Conducting periodic audits of material usage, inventory levels, and procurement processes enables the identification of inefficiencies, discrepancies, and areas for improvement. Regular audits enhance transparency, accountability, and process optimisation.

Just-In-Time Delivery

Adopting a just-in-time delivery approach minimises on-site inventory levels, reduces storage costs, and enhances project flexibility. Just-in-time delivery ensures that materials are delivered precisely when needed, minimising the risk of excess inventory or stockouts.

Material Management Tips

Forecast Accurately

Invest in accurate forecasting methodologies based on historical data, project requirements, and market trends to anticipate material needs effectively and prevent shortages or excess inventory.

Continuous Training

Provide comprehensive training programs to personnel involved in material management to enhance their skills, knowledge, and awareness of best practices, safety protocols, and regulatory compliance requirements.

Embrace Sustainability

Embrace sustainable practices by prioritising the use of eco-friendly materials, implementing recycling initiatives, and minimising waste generation throughout the construction process. Sustainable material management reduces environmental impact and enhances corporate social responsibility.

Effective Communication

Foster open communication channels between project stakeholders to facilitate collaboration, information sharing, and problem-solving. Effective communication minimises misunderstandings, delays, and disruptions in material management processes.

5 Benefits of Material Management in Construction

While building any construction project, the efficient management of materials is very important for its success. From commercial offices to residential buildings to city infrastructure projects, effective material management not only streamlines operations but also enhances overall project outcomes. Let’s delve into the pivotal benefits it offers:

1. Cost Savings

Efficient material management minimises wastage and reduces unnecessary expenditures. By accurately forecasting material requirements and optimising procurement processes, construction firms can reduce costs significantly.

2. Enhanced Productivity

Proper material management ensures that the right materials are available at the right time and in the right quantities. This eliminates delays caused by shortages or incorrect deliveries, thereby maximising workflow efficiency. Workers can focus on construction tasks without disruptions, leading to improved productivity across the project timeline.

3. Time Efficiency

Time is of the essence in construction projects. Through meticulous material planning and scheduling, project managers can expedite timelines and meet deadlines consistently. Timely delivery of materials minimises downtime and prevents project bottlenecks, allowing for smoother progress and timely project completion.

4. Quality Assurance

Using high-quality materials is important for constructing durable and strong structures. Effective material management ensures that only approved materials are utilised, adhering to industry standards and regulatory requirements. This not only upholds the integrity of the construction but also enhances the reputation of the firm for delivering superior-quality projects.

5. Client Satisfaction

Ultimately, successful material management results in client satisfaction. Delivering projects on time, within budget, and to the highest quality standards enhances client trust and loyalty. Meeting or exceeding client expectations fosters positive relationships and paves the way for repeat business and referrals.

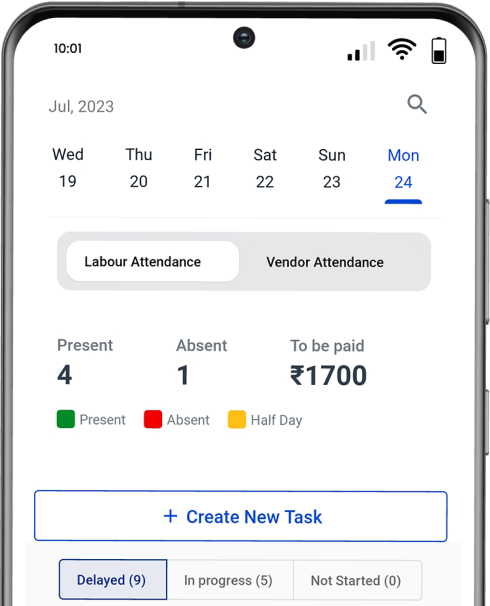

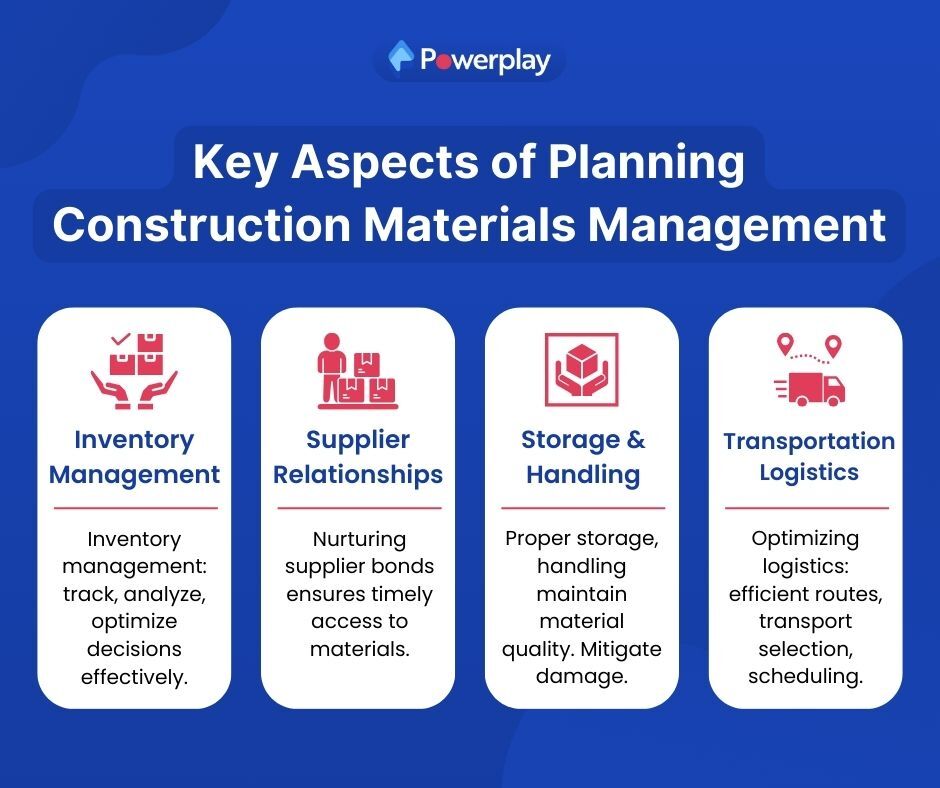

Powerplay – Construction Material Management Apps and Software Systems

Efficient construction material management lies at the heart of successful project execution, encompassing a spectrum of tasks from strategic planning to waste disposal. Powerplay, our innovative construction material management app and software systems, redefine how construction materials are procured, allocated, and managed throughout the project lifecycle.

Powerplay offers a comprehensive suite of digital tools tailored to optimise every facet of construction material management:

Planning and Acquisition

Powerplay simplifies the process of identifying materials that precisely match project specifications, ensuring quality, suitability, and purpose alignment. Our platform facilitates seamless ordering, guaranteeing that materials are procured in optimal quantities to meet project demands.

Scheduling and Transportation

With Powerplay, companies can orchestrate seamless material logistics, ensuring timely delivery to designated construction sites. By eliminating double handling and minimising delays, Powerplay optimises the transportation process for maximum efficiency.

Quality Control

Powerplay empowers users to uphold stringent quality standards by providing real-time monitoring of material quality, ensuring compliance with project requirements and industry specifications.

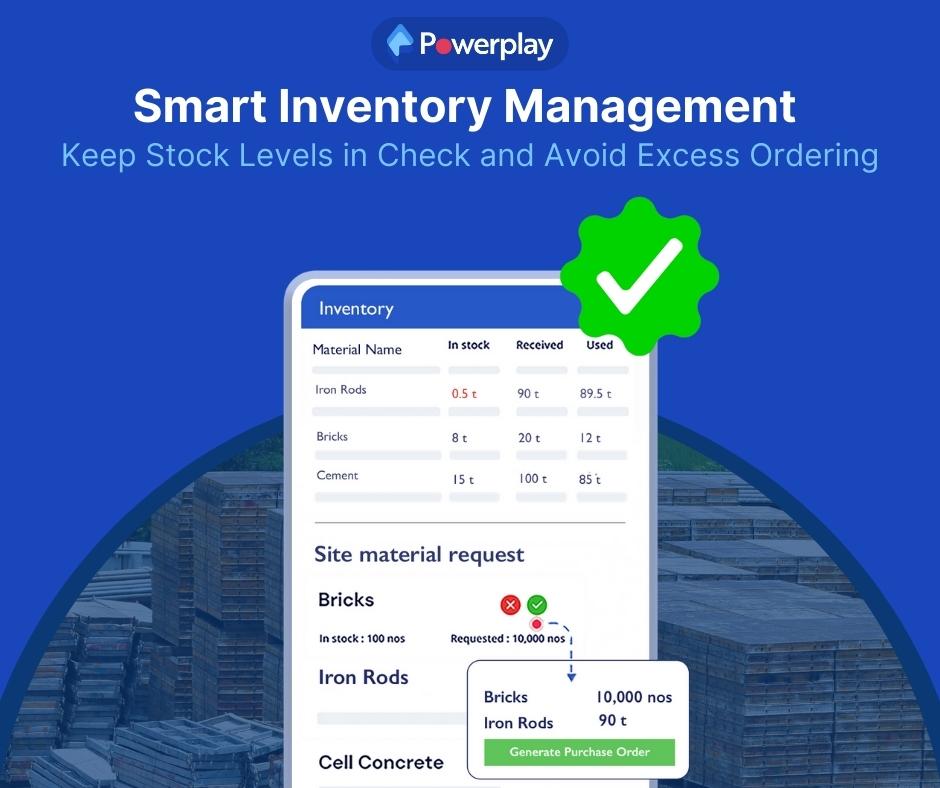

Storage and Inventory Management

Our platform revolutionises inventory management, offering real-time insights into stock levels and consumption patterns. By facilitating regular updates and adjustments, Powerplay prevents resource shortages, thereby averting disruptions to construction activities.

Waste Management

Powerplay enables effective waste tracking and disposal, ensuring adherence to environmental regulations and promoting sustainable construction practices.

The implementation of Powerplay has demonstrated remarkable results, with notable reductions in material wastage and significant improvements in project timelines. Our platform not only facilitates material tracking and management but also plays an important role in generating comprehensive daily material reports and invoices.

By aligning construction material management activities through Powerplay, companies can upgrade to new levels of operational efficiency. Embracing the principles of the “Five Rights” (Rs) – procuring the right materials, in the right quantities, at the right time, delivered to the right place, and at the right price – Powerplay empowers organisations to plan and execute material management strategies with unparalleled precision and effectiveness.

Conclusion

In conclusion, material management techniques have evolved significantly over time to meet the demands of the construction industry. However, our acceptance of these new digital tools seems to be moving at a pace reminiscent of a snail racing against a hare. It’s high time we embraced these technologies that could potentially revolutionise our construction projects.

Share

Kumar is a digital content professional with more than 2 years of experience in Blog writing, copywriting and scripting. His passion lies in the art of creating convincing content that plays a major role in converting leads for SAAS businesses.