8 Best Practices to Improve Construction Site Safety

-

Sapna

- April 5, 2024

Construction site safety is indeed paramount within the industry. However, it is crucial to acknowledge that while accidents occur, the construction sector is actively working to mitigate risks and enhance safety measures.

This industry faces numerous safety challenges, including the high risk of falls from heights, accidents related to heavy machinery and equipment use, and the disclosure of hazardous materials, including asbestos and silica. Many more issues and risks are life-threatening to employees and labour.

According to research, in 2022, the construction industry experienced many accidents, with 1,056 construction workers losing their lives on the job, representing the highest fatality rate in any industry. Additionally, approximately 1% of construction workers suffer a fatal injury each year.

Ensuring the safety of construction workers and site visitors is essential, and implementing best practices will minimise risks and create a safer workplace. In this blog, we will learn about OSHA’s top 10 standards and eight best practices for construction site safety, empower you to prevent accidents and safeguard the well-being of your workforce.

Table of Contents

ToggleOSHA’s Top 10 Standards In Construction

The Occupational Safety and Health Administration (OSHA), a federal agency in the United States, has announced a list of the top 10 standards in the construction industry to help employers identify common worksite hazards and improve safety protocols.

For the financial year 2023, the top 10 most frequently cited standards in construction are:

- Fall Protection: Implement measures to prevent falls from elevated surfaces, such as guardrails, safety nets, and personal fall arrest systems

- Ladders: This standard outlines safety requirements for ladders, including specifications, inspection procedures, and employee training guidelines.

- General Scaffold Requirements: This standard covers fall arrest systems, supported scaffold platforms, and suspended scaffolding, including building and dismantling specifications, training guidelines, and inspection measures.

- Fall Protection Training: This standard is essential for labourers who work at heights and requires training in fall hazards, certifications, and re-training when necessary.

- Eye and Face Protection: This standard requires identifying hazards and supplying employees with proper protection, such as safety glasses, goggles, and face shields.

- General Safety and Health Provisions: This standard requires contractors to provide workers with a safe work environment, including providing first aid kits and basic first aid training, preventing work in hazardous conditions, performing compliance duties, and providing personal protective equipment and training.

- Head Protection: This standard requires providing head protection that meets specifications for different job environments.

- Specific Excavation Requirements: This standard covers requirements for safe surface or underground excavation operations, including proper atmospheres, structural stability, access/egress, usage of Sign boards and emergency rescue equipment.

- Aerial Lifts: This standard requires aerial lifts to conform to applicable national standards, including proper operation, training, and inspection procedures.

- Machine Guarding: Machines must have guards to protect operators and other employees from hazards such as rotating parts, flying chips, and sparks.

Top 8 Best Practices to Improve Construction Site Safety

Improving safety on a construction site is primary. It not only helps to meet legal requirements but also ensures the well-being of all workers involved.

Here are the top 8 best practices to enhance safety on construction sites

Comprehensive Safety Training

Provide thorough training programs for all workers covering hazard recognition, emergency procedures, and the correct usage of safety equipment.

Regular Safety Check

Conduct regular construction site inspections to find potential hazards, rectify deficiencies, and ensure compliance with safety regulations.

Effective Communication

Foster open communication channels between workers, supervisors, and management to address safety concerns and implement corrective actions promptly.

Pre-Task Planning

Encourage pre-task planning sessions to assess potential risks, develop safety protocols, and allocate resources effectively before commencing work activities.

Promotion of Safety Culture

Cultivate a safety-conscious workplace culture by recognizing and rewarding safe behaviours, fostering peer accountability, and promoting continuous improvement in safety practices.

Emergency Preparedness

Develop and regularly review emergency response plans, conduct drills, and ensure the availability of first aid supplies and trained personnel to respond promptly to accidents or injuries.

Safe Equipment Operation

Provide proper training and certification for equipment operators, conduct regular maintenance checks, and enforce safe operating practices to prevent accidents involving machinery and vehicles.

Continuous Learning and Improvement

Encourage workers’ feedback, analyse incident reports, and seek opportunities for ongoing education and improvement in safety measures and procedures.

Construction Site Safety Checklist

A construction site safety checklist is a vital tool to ensure that all necessary safety measures are in place to protect workers and comply with regulations.

Here’s a checklist that can be adapted to most construction projects:

- Personal Protective Equipment (PPE)

- Fall Protection

- Electrical Safety

- Tool and Machinery Safety

- Hazard Communication

- Emergency Preparedness

- First Aid and Medical Assistance

- Fire Prevention and Protection

- Housekeeping

- Training and Awareness

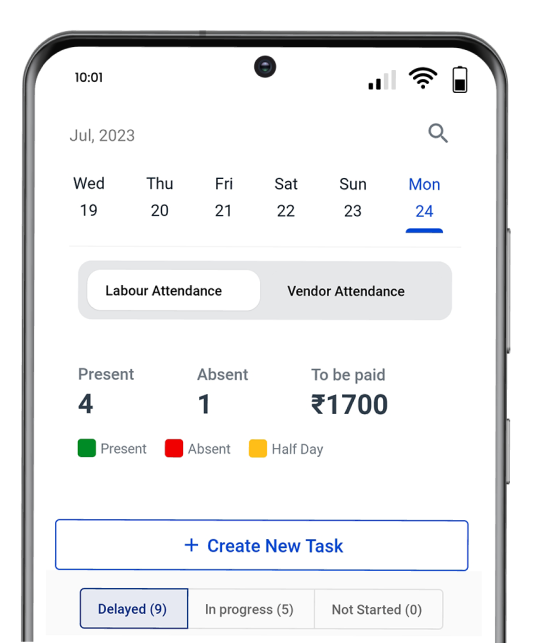

How Powerplay can Assure Construction Site Safety

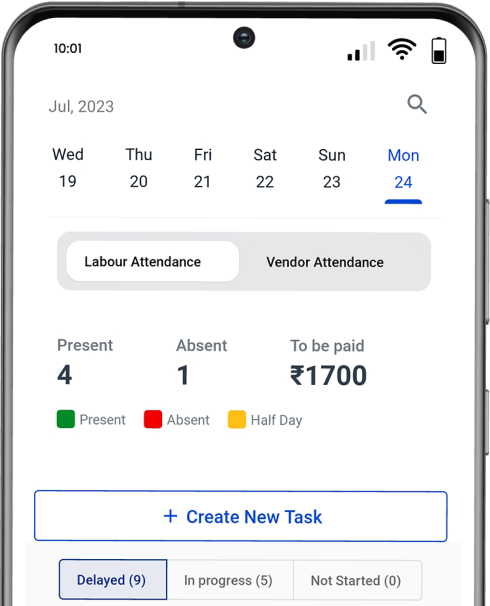

Powerplay is India’s trusted construction management software, equipped with features designed to bolster construction site safety, streamline project management, and foster effective communication.

Here’s how Powerplay can help ensure construction site safety, with a focus on material quality, proper equipment usage, and clear communication:

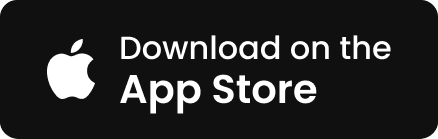

Material Quality and Proper Equipment Management

Powerplay offers features that allow project managers to monitor and verify the quality of materials received on-site. If any material has an issue, project managers can immediately raise issues within the Powerplay platform. Addressing material quality issues will significantly help reduce accidents caused by defective materials.

Clear and Open Communication

The chatbox feature provides a direct line of communication between project managers, workers, and other stakeholders. With this real-time communication tool, users can discuss safety measures, share updates, and address concerns as they arise.

Conclusion

In conclusion, the importance of construction site safety cannot be emphasised enough. Ensuring site safety is vital for maintaining the well-being of workers. And maintaining the reputation of construction companies, and the overall success of projects.

Adhering to OSHA standards and implementing these practices will protect your workers. It will foster a culture of safety, which will help increase productivity and create a positive working environment.

By prioritising construction site safety, companies ensure the well-being and safety of everyone involved. And also minimise liabilities and potential disruptions to project timelines. Investing in safety measures pays off in the long run, leading to better project outcomes and enhanced industry reputation.