Improving Supply Chain Efficiency in Construction Materials Management

-

Kumar Abhishek Anand

- October 10, 2023

Construction projects involve the complex coordination of various resources, including labor, equipment, and materials. Among these resources, the management of construction materials plays a crucial role in ensuring the smooth progress and timely completion of projects. However, the traditional methods of inventory and supply chain management in the construction industry often face numerous challenges that can hinder efficiency and productivity.

In this article, we will explore the importance of inventory management in the construction industry and delve into the issues that arise at each step of the supply chain. We will also introduce the hero of the story – inventory management software – and how it can address these challenges to optimize construction materials management.

Table of Contents

ToggleConstruction Inventory Management

Construction projects rely on a vast array of materials, ranging from bricks and cement to electrical wiring and plumbing fixtures. Managing these materials efficiently is essential to prevent delays, minimize costs, and avoid disruptions to project schedules. Unfortunately, many construction companies struggle with various issues when it comes to inventory management.

Some of the challenges faced in construction inventory management include:

1. Inaccurate forecasting: Estimating the required quantity of materials for a project can be a daunting task, often leading to overstocking or understocking of materials. This often results in unnecessary capital tied up in excess inventory or project delays caused by insufficient materials.

2. Lack of visibility: Due to the vast scale of construction projects and the involvement of multiple stakeholders, tracking and monitoring inventory across different sites can be a complex process. This lack of visibility can lead to misplacements, theft, or loss of materials, further impacting project timelines and budgets.

3. Manual processes: Many construction companies still rely on manual methods to record and track inventory, such as spreadsheets or paper-based systems. These manual processes are time-consuming, prone to human errors, and often lack real-time updates, making it difficult to maintain accurate inventory records.

4. Inefficient ordering: Ordering materials from suppliers is a crucial step in the construction materials management process. However, inefficient ordering practices, such as delays or errors in purchase orders, can result in delays, inflated costs, or even project stoppage.

What is Inventory Management, Its Function, and Its Importance?

Inventory management involves the effective planning, control, and monitoring of materials throughout the supply chain. It ensures that the right materials are available at the right time, in the right quantity, and at the right location, while also minimizing inventory holding costs.

The primary functions of inventory management in construction materials include:

1. Demand forecasting: Estimating the required quantities of materials based on project specifications and schedules.

2. Supplier coordination: Identifying suitable suppliers, negotiating contracts, and managing relationships to ensure timely and cost-effective material procurement.

3. Receiving and storage: Efficiently receiving, inspecting, storing, and organizing materials in designated areas to facilitate easy accessibility and reduce the risk of damage or loss.

4. Issuing and tracking: Issuing materials to job sites as required, while maintaining accurate records and tracking their movement within the supply chain.

5. Inventory control: Monitoring inventory levels, setting reorder points, implementing safety stock measures, and optimizing inventory turnover to prevent shortages or excess stock.

6. Waste management: Minimizing waste through proper material handling, storage, and utilization, contributing to sustainability efforts and reducing costs.

Effective inventory management is crucial for construction projects as it offers several benefits, including:

a. Optimized project timelines: Having the right materials available at the right time helps prevent delays caused by material shortages or supply chain disruptions.

b. Reduced costs: Efficient inventory management minimizes excess inventory, optimizing storage space and reducing holding costs.

c. Improved productivity: Streamlined processes in inventory management lead to increased efficiency and productivity by reducing manual efforts and time spent searching for materials.

d. Enhanced coordination: Accurate inventory records and real-time updates enable better coordination among project teams and stakeholders, allowing for effective planning and decision-making.

Problems in Inventory and Supply Chain Management at Each Step

The construction material supply chain involves multiple steps, from procurement to delivery to the construction site. Each step presents its unique challenges that can hinder the smooth flow of materials. Let’s take a closer look at the problems faced at each stage:

1. Procurement: Inefficient procurement processes can lead to delays, errors, and higher costs. Challenges include inaccurate demand forecasting, lack of visibility into supplier performance, and problems with supplier coordination.

2. Transportation and delivery: Transportation issues, such as delays, damaged goods, and poor coordination, can disrupt the entire supply chain. Lack of real-time tracking and visibility into transportation logistics can further exacerbate these problems.

3. Receiving and storage: Manual recording of received materials can result in errors, while inadequate storage or disorganized inventory can lead to difficulties in locating materials when needed.

4. Issuing to job sites: Inaccurate tracking and lack of visibility into material availability can cause delays and can result in material shortages or excesses at the construction site.

These challenges significantly impact the overall efficiency and productivity of construction projects and highlight the need for a more streamlined and automated solution.

The Hero – How Inventory Management Software Helps?

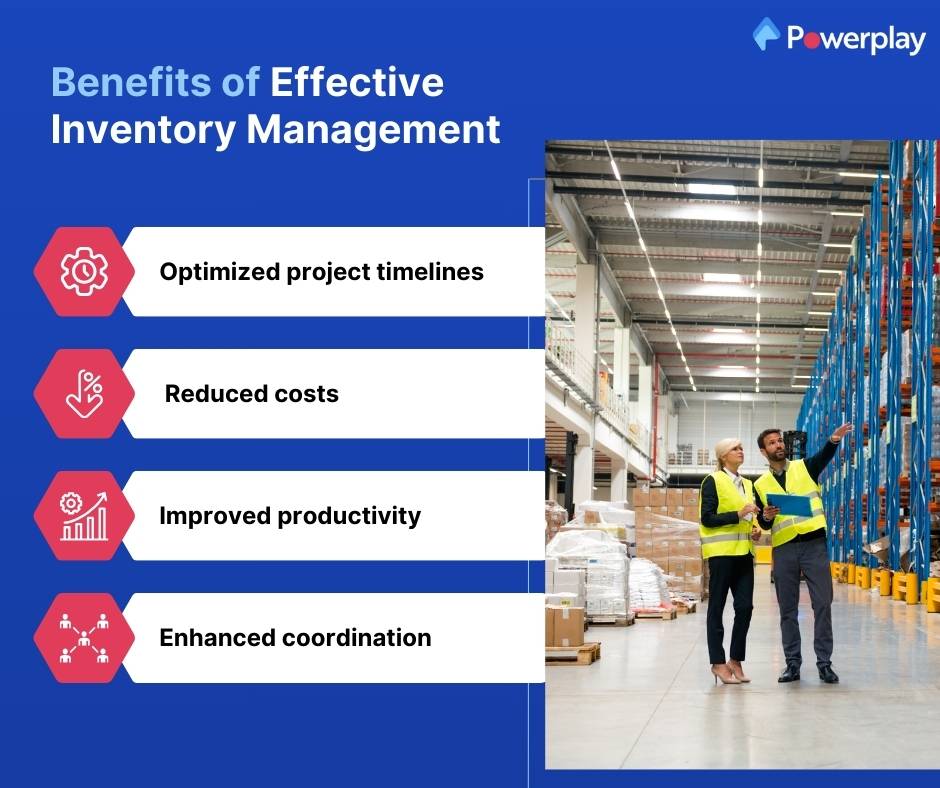

Fortunately, advancements in technology have paved the way for inventory management software specifically designed for the construction industry. From procurement to material tracking, these software solutions bring substantial benefits to construction materials management.

Benefit 1. Streamlined procurement: Inventory management software automates the entire procurement process, integrating it with demand forecasting, supplier management, and workflow approvals. This helps minimize errors, reduce delays, and enhance coordination with suppliers.

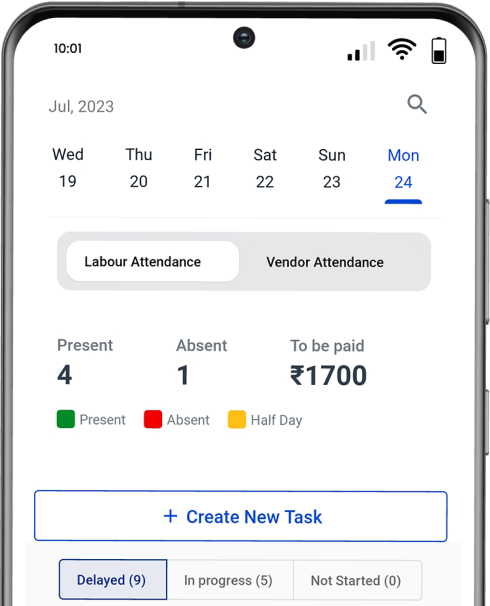

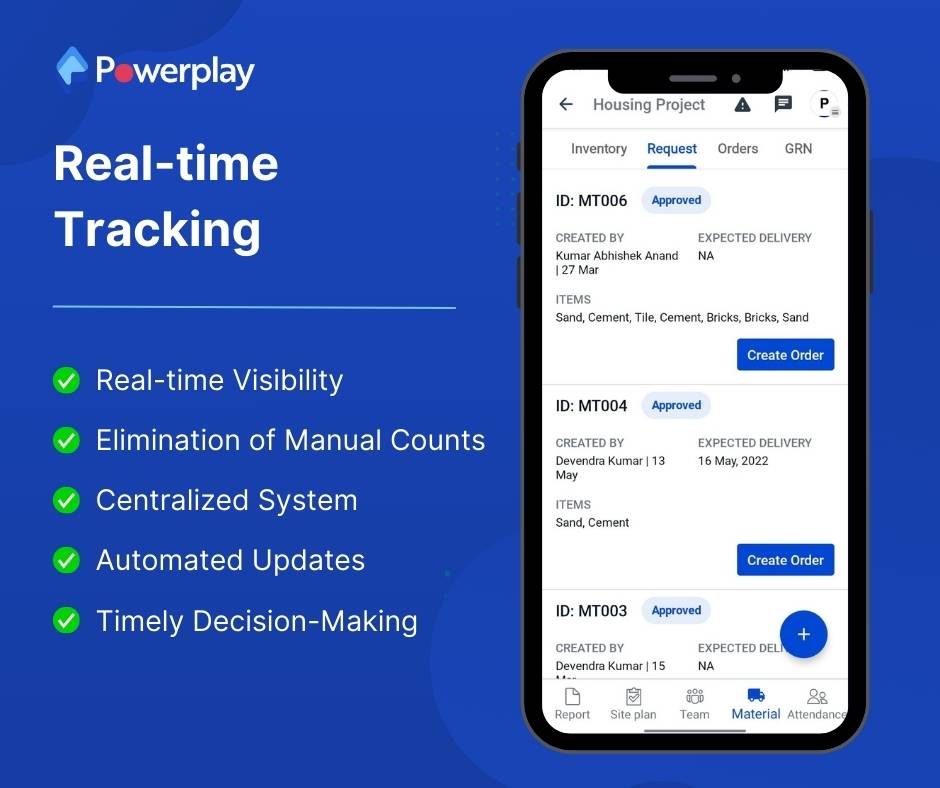

Benefit 2. Real-time tracking: With inventory management software, real-time tracking of materials becomes possible, providing visibility into their movement within the supply chain. This enables efficient transportation logistics, reduces the risk of loss or theft, and improves overall supply chain coordination.

Benefit 3. Efficient storage and organization: By digitizing inventory records and implementing barcode or RFID tracking, inventory management software ensures accurate recording and easy retrieval of materials. This minimizes errors and saves time spent searching for specific items.

Benefit 4. Automated issuing and tracking: Software solutions enable automated issuance of materials to job sites, with real-time updates on material availability. This prevents delays, reduces paperwork, and ensures adequate stock levels at all times.

Benefit 5. Data-driven decision-making: Inventory management software provides comprehensive analytics and reporting capabilities, allowing construction companies to make informed decisions based on accurate data. This leads to greater efficiency, reduced costs, and improved project outcomes.

Conclusion – Digital Inventory Management is the Future

The construction industry is poised to benefit greatly from the implementation of digital inventory management systems. With their ability to automate processes, provide real-time visibility, and improve overall supply chain coordination, construction companies can significantly enhance their productivity, reduce costs, and ensure timely project completion.

The challenges faced in inventory and supply chain management in the construction industry can be overcome with the right technology solution. By leveraging inventory management software tailored to their specific needs, construction companies can optimize material utilization, streamline operations, and pave the way for a more efficient and sustainable future.

In conclusion, embracing digital inventory management is not only a strategic move for construction companies, but it is also a necessity in today’s competitive industry landscape. With its ability to address the challenges and improve efficiency at each step of the supply chain, inventory management software is undeniably the hero that construction materials management needs.

Share

Kumar is a digital content professional with more than 2 years of experience in Blog writing, copywriting and scripting. His passion lies in the art of creating convincing content that plays a major role in converting leads for SAAS businesses.