3D Printing in Construction

-

Kumar Abhishek Anand

- October 23, 2023

3D printing, also known as Additive Manufacturing(AM) is the continuous layering of construction materials to create 3D shapes and structures. The complete process is computer-controlled and can be better described as a computer-aided design. The 3D model can also be designed using 3D scanners.

3D printing can create construction elements or print entire structures in the construction industry. Depending on the printing method used, different sets of materials and colours can be used to print individual or multiple components simultaneously. The accuracy of printing models can be increased by high-resolution subtractive processes. The usage of computer-aided design in the construction industry has existed for some time, and the recent development of building information modelling(BIM) has facilitated better and greater use of 3D printing.

Table of Contents

ToggleDifferent Technologies Used in Construction

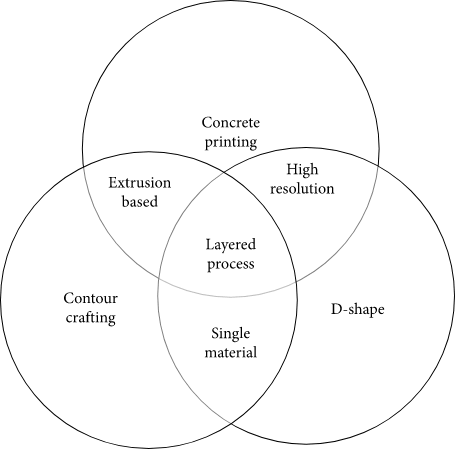

Some of the different 3D printing technologies that are being used in the construction industry are:

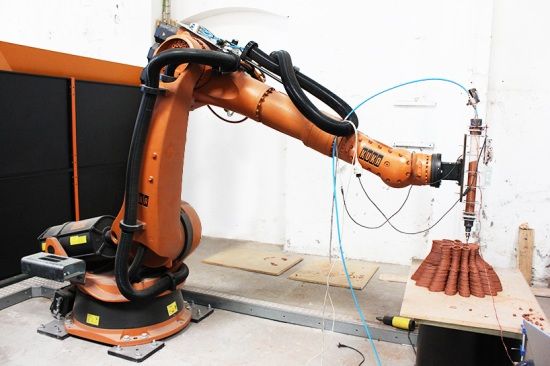

1. Robotic Arm Extruders– This technology is called contour crafting. Rails are arranged across and around the structure to move the robotic arm that builds the house layer by layer by extruding concrete mixture from the nozzle attached to the robotic arm. Trowels are placed on the side and above the nozzle to flatten the concrete and ensure design strength. Quick-setting concrete is used for this technology as the consequent layers can be placed only after the previous layer of concrete has hardened.

2. Sand Layers Printing– The 3D printing machine used in this technology spreads a layer of sand powder and then from the print head pours binder droplets to harden the sand. This process is repeated and can be ultimately used to create structures of upto 6m3.

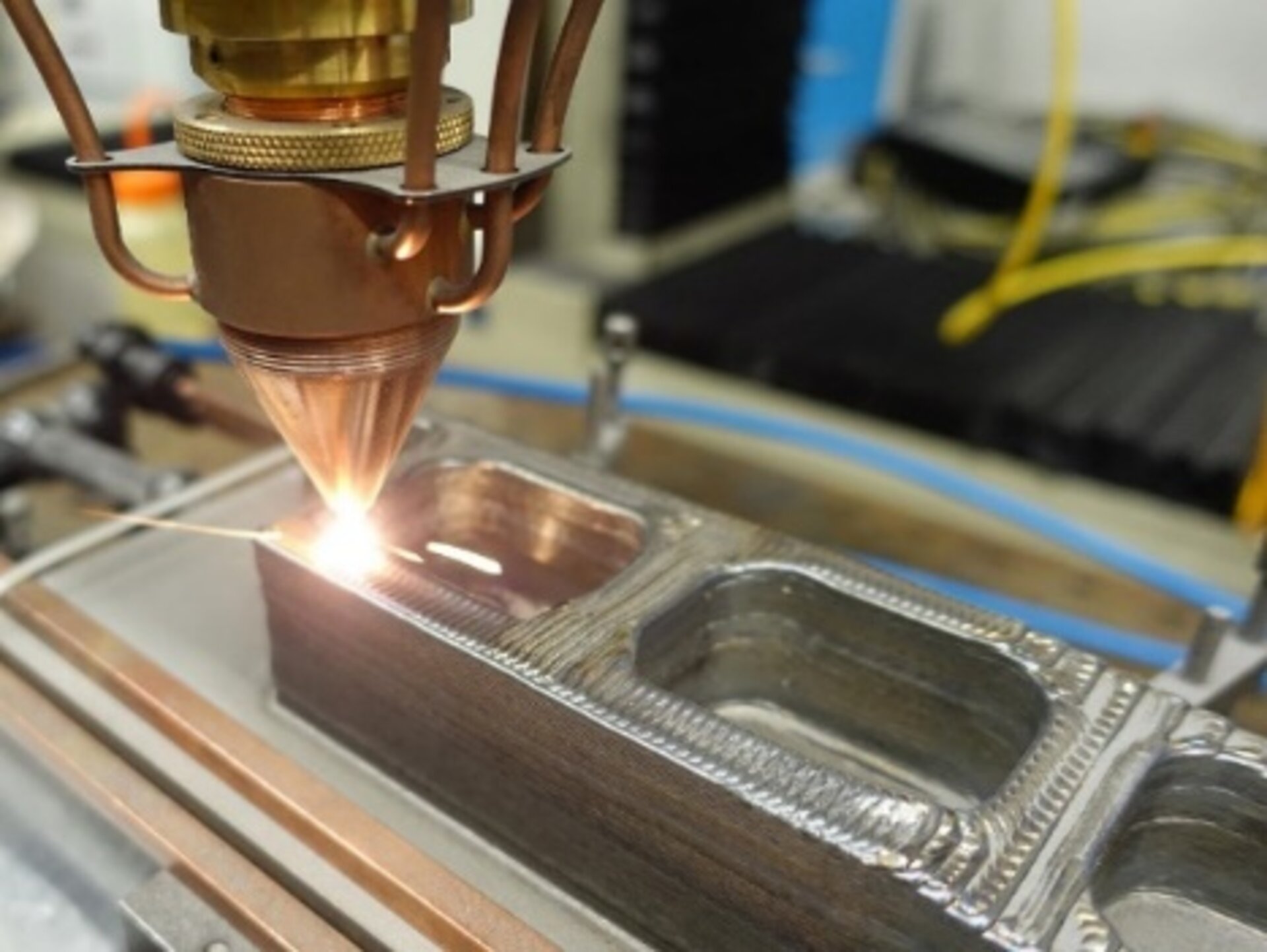

3. Metal Technology– This is based on a unique construction technique named Wire Arc Additive Manufacturing(WAAM). This method lets you 3D print metal structured with a 6-axis robot that drops 2 kgs of material per hour.

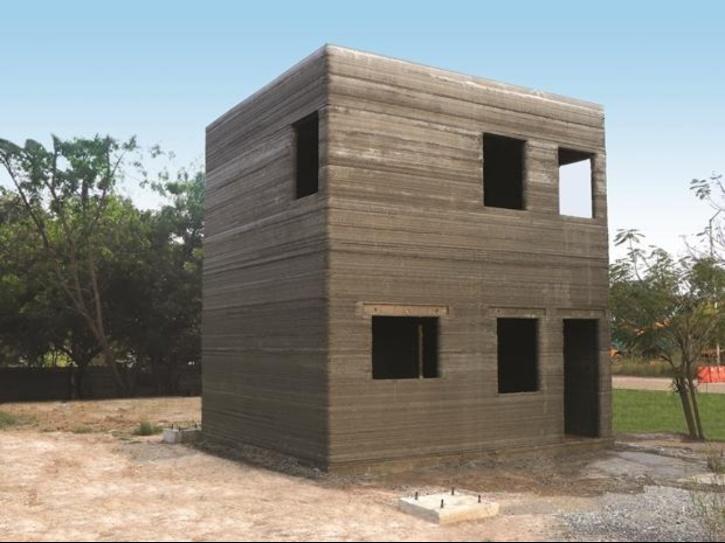

The first trial in India was done when construction Giant L & T successfully 3D printed a 700 sq ft building(G+1 floor) with reinforcement. The building was printed at a location in Kanchipuram using a fully automated printer and locally developed concrete mix, using indigenously available materials. Both vertical reinforcements and horizontal distributors were used to print the building with the help of welded mesh laid according to the codal provisions. The entire building structure, except the horizontal slab components, was 3D printed and cast in situ at the construction site in 106 hours. This is a landmark moment in Indian Construction history.

Advantages of 3D Printing

The usage of 3D printing in the construction industry is growing rapidly because of its advantages and prominent functions. Some of the major advantages of using 3D printing in construction are

Innovative and Flexible Design- AMs create space for innovations as 3D structural visual models can be designed at the planning stage to satisfy the client’s design requirements. 3D printing presents contractors with viable options to construct more complex designs than traditional manufacturing processes.

Rapid Production– Production time of structures are greatly reduced when 3D printing methods are used. Approximately a 500-800 sq ft house can be built within a day. 3D printing processes are fully automated and free of human error, the only effort that needs to be put in is monitoring of the printing process. It does not need any external assistance during the construction process as the design structure has been programmed and the printer can perform all functions ranging from printing of simultaneous layers to printing with different materials.

Minimal Wastage– Almost zero waste is produced during and after the 3D printing process. Recycled materials can also be used instead of traditional supplies in 3D printing, which reduces the impact on the environment to a vast extent. Not only is wastage of materials prevented but costs related to materials are greatly reduced.

Cost Effective– As mentioned above, the costs are greatly reduced due to less material usage and less demand from the workforce for printing. Additionally, it is cost-effective in terms of less time used for completing buildings. In other words, 3D printing uses fewer materials and labour hours, thus cutting overall expenses.

Strong and Lightweight Products– Most construction components built using 3D printing technology are lighter and stronger than their traditional counterparts.

Easy to Use– 3D printing technology is becoming more accessible to service providers. It aids them in acquiring more projects and providing them with outsourcing opportunities. There is no need to put in extra effort to transport materials and pieces of equipment, thereby reducing transportation costs.

Don’t wait! Power Up Your Construction with Powerplay today!! Request a Demo to learn more.

Share

Kumar is a digital content professional with more than 2 years of experience in Blog writing, copywriting and scripting. His passion lies in the art of creating convincing content that plays a major role in converting leads for SAAS businesses.