3 Types of Industrial Buildings

-

Kumar Abhishek Anand

- October 23, 2023

Industrial buildings represent one of the four commercial buildings that manufacture, store, and pack products for shipment. In other words, an industrial building is a typical factory or larger facility. It serves one or more business purposes, such as manufacturing, remodelling, power generation, repair, and cleaning. These building types are very different from other commercial buildings such as office buildings and commercial buildings.

Industrial buildings fall into three main categories: manufacturing, warehousing & distribution, and flexible space. These industrial building types can serve multiple purposes, depending on the space and resources available within its reach.

Due to special rules for industrial buildings, they cannot be constructed anywhere in the city. They must also comply with the area’s laws to balance the environment and society.

Table of Contents

ToggleDifferent Types of Industrial Buildings

Type #1 – Manufacturing Buildings

As the name implies, a production building is a business facility where goods are manufactured and assembled. Standard industrial buildings comprise less than 20% of the loading area for large vehicles and office space. A minimum of 10 feet of headroom is required for the entire building.

Production buildings can feature not only powerful pieces of equipment but also highly specialized building structures and final designs. Ventilation systems, ducts, drains, water, gas, or chemical pipelines can also be installed, depending on your business needs.

Manufacturing buildings are mainly of two types: Heavy manufacturing buildings and Light assembly buildings.

01 – Heavy Manufacturing Buildings

The heavy production building is where products such as prefabs, trucks, and other outdoor equipment are manufactured and serve as the starting point. These buildings include a large-scale automated production system with 24/7 production capabilities. For this reason, it is built on a vast area of hundreds of square meters not only to manufacture products but also to provide storage facilities for goods produced daily.

Mass-produced buildings must have three-phase power and a huge docking area to handle mass-produced goods. If we need to change the production potential, structure, or ownership of the production building, we will completely renovate the entire building. This is because we will need to relocate some permanent production systems that manufacture specific products to adjust to the new designs and regulations.

02 – Light Assembly Buildings

Products that can be manufactured with smaller or lighter manufacturing systems are manufactured in lightweight assembly plants. These building types must not have permanently installed assemblies or large supply units.

Because production machines are small or lightweight and easy to carry, refurbishing a building is relatively easy if ownership or products change. The lightweight assembly building may also include a smaller storage area to accommodate a limited number of products awaiting shipment.

Type #2 – Storage and Distribution Buildings

Logistics and distributors or owners like Flipkart who ship products to end-users and perform similar functions need warehouses and distribution buildings for their business. Less than 10% of the total building area is dedicated to office space and the remaining area is used for storage and distribution functions.

Warehouse buildings are typically one-story and have a large area of thousands of square feet. They have higher ceilings, more cargo areas, and numerous vehicle yards. There are relatively few employees working in these types of buildings and few customers. As a result, less parking space is required compared to other types of industrial buildings.

It is very important to build these storage and distribution buildings in areas where they can be transported, as most of the business is done by truck. These locations are suitable near the boundaries of highways and interstates, so heavy trucks can easily catch up with the major roads that connect the major locations. If the goods are of particular importance, if long-distance transportation is required, or if they are part of an international transaction, the storage building should be located near the airport.

Storage and distribution buildings are mainly of three types – General Warehouses, Distribution Warehouses, and Truck Terminals.

01 – General Warehouse Buildings

General warehouses store products manufactured and assembled in the manufacturing building. They can be specially configured, like refrigerated warehouses for fresh produce, to maintain product quality.

The location aspect does not play a major role in these buildings, as the goods must be stored for much longer. The movement of goods into and out of the facility is so small that even the space required to move the goods inside the building is less important.

The space design in these buildings is tailored to the products being stored, leading to varying prices across different storage facilities. For instance, a refrigerated warehouse equipped with a freezer requires a sealed dock and an insulated cross-dock door to ensure the integrity of the stored products.

02 – Distribution Warehouse Buildings

As the name itself suggests, the main purpose of using a distribution warehouse is to ship goods from the terminal. Therefore, the location of sales buildings is an essential element of business prosperity, and these buildings are located near important transportation routes, train stations, and airports.

To ensure easy and fair service to the customer based on product demand, the distribution centre should be located at the centre of the demand area. This also allows distributors to process orders as quickly as possible, regardless of the customer’s location.

03 – Truck Terminals

A truck terminal is an intermediate loading and unloading station that acts as an intermediate station for transferring goods from one truck to another. The space required to build a truck terminal is the smallest of all types of industrial buildings, most of which can speed up the product transfer process.

Type #3 – Flex Space Industrial Buildings

Flexspace buildings, designed for versatility, serve various functions, including acting as production units with storage facilities. These flex buildings offer customization to meet specific business needs and present fewer refurbishment challenges than traditional industrial buildings. These hybrid spaces can consist of office areas, showrooms, warehouses, and other business needs.

These buildings have slightly lower ceilings than other industrial buildings. Over 30% of the space in these buildings is allocated for office use, accompanied by ample parking. This arrangement particularly benefits startups, saving them significantly on office rent.

Flex space buildings are mainly of three types – Research and Development buildings, Datacenter buildings, and Showrooms.

01 – Research and Development(R&D) Buildings

The R&D building is needed for companies to test and develop new products and services and improve existing products. As a result, companies need R & D buildings with specialized build and test space that can include free space for builds, lightweight manufacturing facilities, and open areas for testing.

The R & D building creates products solely for testing and prohibits commercial use. Recently, the design of R & D buildings has expanded to encompass a business campus area, featuring a unified architectural style for all individual buildings, extensive parking, and a visually appealing aesthetic with open spaces.

02 – Datacentre Buildings

A data centre is a purpose-built facility that stores servers and other networking equipment for the purpose of data storage, management, and dissemination. It also stores data related to business and customers. The area required to build a data centre is large, generally exceeding one lakh square feet.

For network equipment to operate smoothly 24 hours a day, it is necessary to install a special cooling system and an emergency generator to maintain the operating efficiency of the equipment. You also need to provide an appropriate security system to protect expensive equipment. When designing floors for network equipment, it is essential to ensure that they are reinforced to withstand heavy loads.

03 – Showroom Buildings

A perfect example of a flex building, it has office space, storage space, and showroom space. Generally, businesses use more than half of the building area to display and sell products.

The most common examples of showroom buildings are car dealerships, furniture companies, and electronics stores.

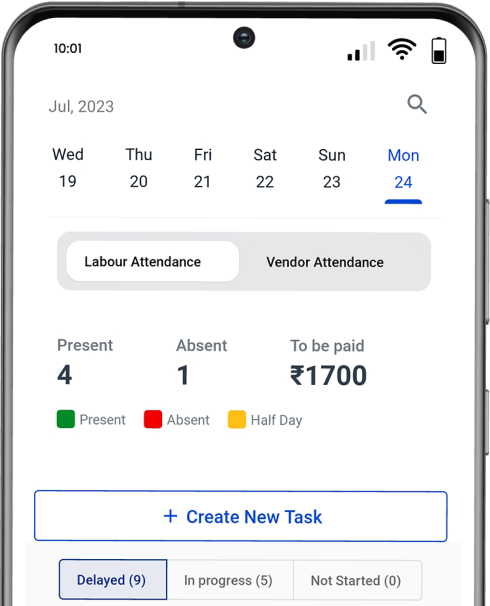

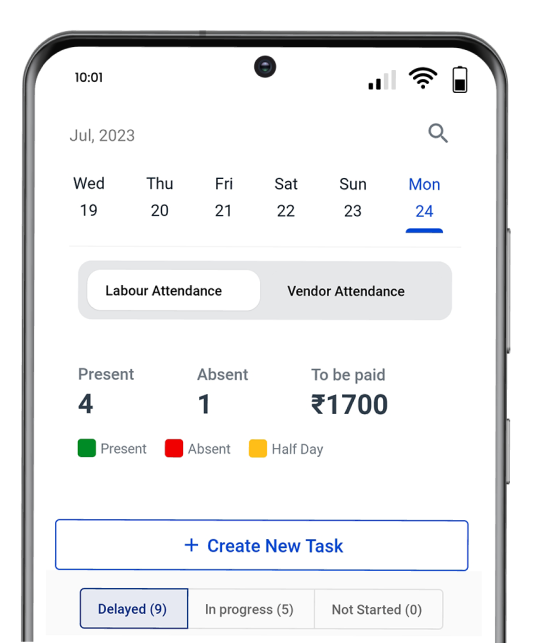

The Indian construction industry is growing rapidly. We need a robust construction project management system to oversee and regulate construction projects organizationally. Powerplay is India’s first construction management software – track all your construction sites’ proceedings and post updates related to them. Create all construction reports from inventory management to DPRs, in no time. To top it all, the in-app chat feature and update feed let you in on recent real-time developments.

Be Smart and Fast with Powerplay.

Share

Kumar is a digital content professional with more than 2 years of experience in Blog writing, copywriting and scripting. His passion lies in the art of creating convincing content that plays a major role in converting leads for SAAS businesses.